What are Thermally Broken Lintels?

Thermally broken lintels are structural elements used in building construction to support the load of the masonry above openings such as doors and windows. The term "thermally broken" refers to a design that minimizes the transfer of heat between the inner and outer parts of the lintel.

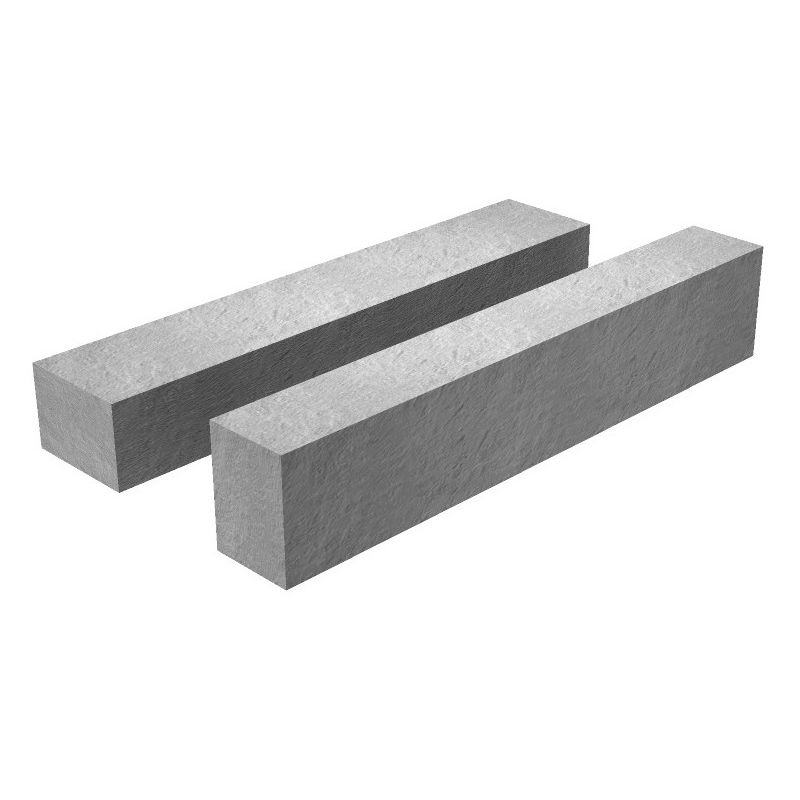

Traditional lintels, made from materials like steel or concrete, can conduct heat from the outside to the inside of a building, leading to thermal bridging. Thermal bridging occurs when there is a direct path for heat to flow through a building element that is more conductive than the surrounding materials, resulting in energy loss and potential condensation issues.

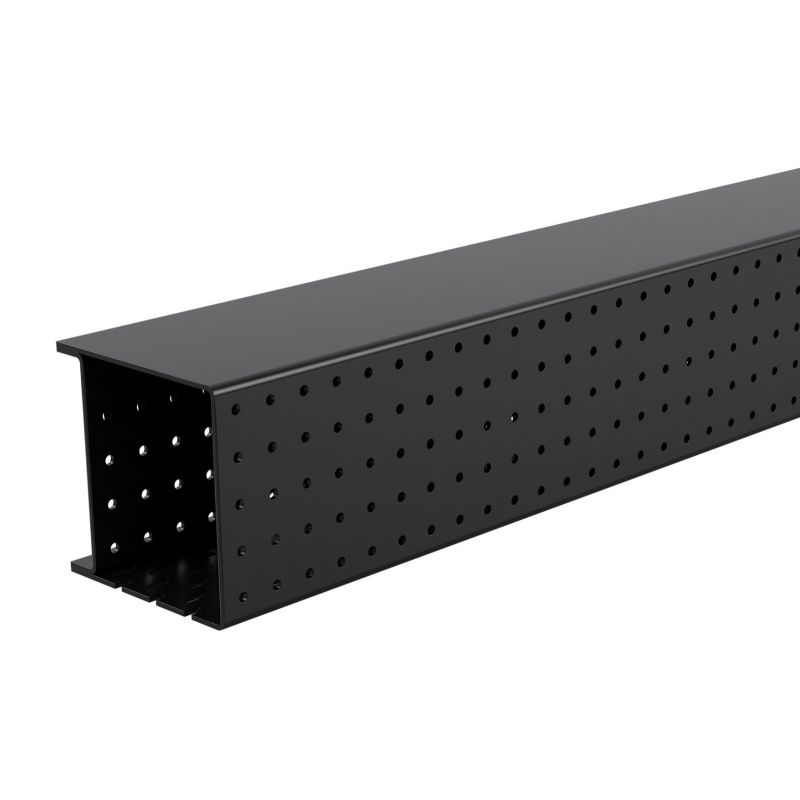

Thermally broken lintels address this problem by incorporating a thermal break—a material with low thermal conductivity—between the inner and outer sections of the lintel. This break helps to reduce the heat transfer, improving the overall thermal performance of the building envelope.

What are the benefits of Thermally Broken Lintels?

Common materials used for the thermal break in thermally broken lintels include materials with low thermal conductivity, such as polymers or insulating materials. These materials help prevent the direct flow of heat from the exterior to the interior, contributing to better energy efficiency and potentially reducing heating and cooling costs in a building.

Thermally broken lintels are particularly beneficial in structures where energy efficiency and thermal performance are important considerations, such as in sustainable or energy-efficient building designs.

Thermally broken lintels offer several benefits in building construction, particularly in terms of energy efficiency and overall thermal performance. Here are some of the key advantages:

- Reduced Heat Transfer: The primary benefit of thermally broken lintels is their ability to minimize heat transfer between the exterior and interior of a building. The thermal break interrupts the path of heat, reducing thermal bridging and helping to maintain a more consistent indoor temperature.

- Improved Energy Efficiency: By minimizing heat loss or gain through the lintel, thermally broken lintels contribute to the overall energy efficiency of a building. This can lead to lower heating and cooling costs, as the building's HVAC systems don't have to work as hard to maintain a comfortable temperature.

- Condensation Prevention: Thermal bridging can contribute to condensation issues within a building, leading to moisture problems and potential damage. Thermally broken lintels help mitigate condensation by reducing the likelihood of cold spots on the interior surfaces.

- Enhanced Comfort: Buildings with improved thermal performance often provide a more comfortable living or working environment. Consistent indoor temperatures and reduced drafts contribute to occupant comfort.

- Compliance with Energy Codes: Many building codes and energy efficiency standards require compliance with specific thermal performance criteria. Using thermally broken lintels can help meet these requirements and ensure that a building meets or exceeds regulatory standards.

- Sustainable Design: Thermally broken lintels align with sustainable and energy-efficient building practices. They contribute to the overall sustainability of a structure by reducing energy consumption and environmental impact.

- Long-Term Durability: The materials used in thermally broken lintels are often chosen for their durability and resistance to corrosion. This can contribute to the long-term structural integrity of the building.

- Design Flexibility: Thermally broken lintels are available in various shapes and sizes, offering design flexibility for architects and builders. This allows for the incorporation of energy-efficient features without compromising on aesthetics or structural requirements.

In summary, the use of thermally broken lintels can lead to improved energy efficiency, occupant comfort, and long-term sustainability, making them a valuable component in modern building construction, especially in regions with varying climates and stringent energy efficiency standards.